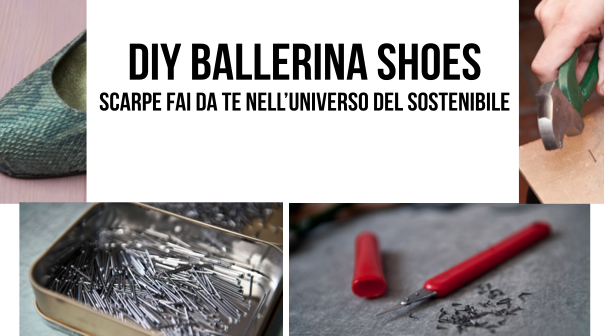

DIY SHOES

DO IT YOURSELF SUSTAINABLE SHOES

Textile and Leather recycling

Reusing or Reprocessing of used clothing and bags

The use of recycled materials in textile

garments and footwear is very popular today

VEGETABLE TANNED LEATHER FROM RECYCLED JACKET

This year the principle of sustainability in IFA’s mission is expressed by planning DIY workshops not only addressed to the use of natural and organic raw materials but also to the concept of eco-friendly production proposing the use of recycled materials: garments no longer used and left in our wardrobes for some time such as leather jackets, leather or suede pants, denim jackets and trousers.

Our partner

This workshop is open to all.

Tutors:

Agostina Zwilling Artist and Ecofashion Designer

Cecilia Serafini Fashion Designer specialized in footwear

Teaching languages: Italiano/English

--------

For participants DIY SHOES’ class

we have an invitation from Italoforme to visit their premises where the shoeforms are made.

23 April, 2012 at 12:30

During the first years of its activity, the company developed a handicraft activity

of production of wooden lasts for shoe manufacturing.

Nowdays, company in continual evolution, with the enterprising generation,

wants to bet in on innovative organizing ability, with past roots but with ideas turn to the future.

It has used the experience accumulated through the years for the realization of the first

prototype in the world which is able to realize and to change, through CAD-CAM, a finished product.

The modelling company has highly qualified personnel capable of satisfying customers with accurate knowledge and technical service for the construction of wooden prototypes aimed at world markets.

The in-company training and the constant and continuous contact with careful and scrupulous designers include the company among the best Italian and international mould producers.

The first prototype is made of wood, it is modified according to the needs of customers with a very accurate manual work, once perfected the wooden model is scanned with optical instruments and the resulting file is forwarded to serial production developed in recycled plastic material.

The working environment has improved in recent years both in terms of quality - with the introduction of highly specialized and cutting edge machinery – and in terms of hygiene/ health requirements in regards to noise emissions, powders and safety.

In 2007 we achieved ISO 14001 environmental certification.

No pollution is produced and/or generated from the production cycle, the plastic material considered hazardous waste from landfills being retrieved to regenerate it and reintroduce it as a raw material in the first moulding step of their business.

23 to 25 April, 2012

Verona Italy